Extensive Range of Premium Concrete Products for Your Construction Needs

With everything from basic grey to long-lasting colour mixed concrete our quality range is cost effective and attractive on its own or textured with aggregates.

7 Concrete Plants across

South East QLD and Northern NSW

With everything from basic grey to over 50 long-lasting colour mixed concretes, our quality range is cost-effective and attractive on its own or textured with aggregates.

Please contact one of our friendly Concrete & Decorative Advisors for further assistance with your selection, or visit our customer display areas to view physical samples at:

NUCRUSH HEAD OFFICE, Hart Street Upper Coomera 4209 - Display open Monday to Friday, 8 am to 3 pm (excluding public holidays).

NUCON CONCRETE SOUTHPORT, Southport Nerang Road Southport 4215 - Display open Monday to Friday, 8 am to 2 pm (excluding public holidays).

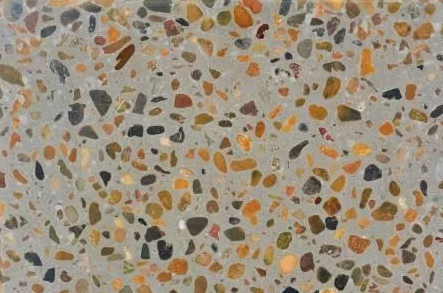

Nu Decorative® Exposed Aggregate Concrete - Driveways, Pools & More

One of the most versatile and attractive flooring options, exposed concrete provides a degree of grip that is particularly suited for driveways, pool surrounds and patios. A long-wearing and high-quality product that can last a lifetime. See below some examples of mixed aggregates and concrete; multiple colour combinations are available to suit your design requirements, including colour matching of existing concrete.

Note - Exposed concrete may vary in appearance due to the size of the stone, concrete placement, and intensity of exposure. The samples pictured are intended to act as a guide only and not an exact representation of the finished product; due to environmental factors and the natural raw materials used, the appearance may also vary. We recommend viewing a physical sample prior to purchase. Please read our 'Nucon Product Guide for Exposed Aggregate Concretes' for further information. Images are provided as a guide only. Colour reproduction can vary significantly when viewing colours on your computer screen and other electronic mobile devices.

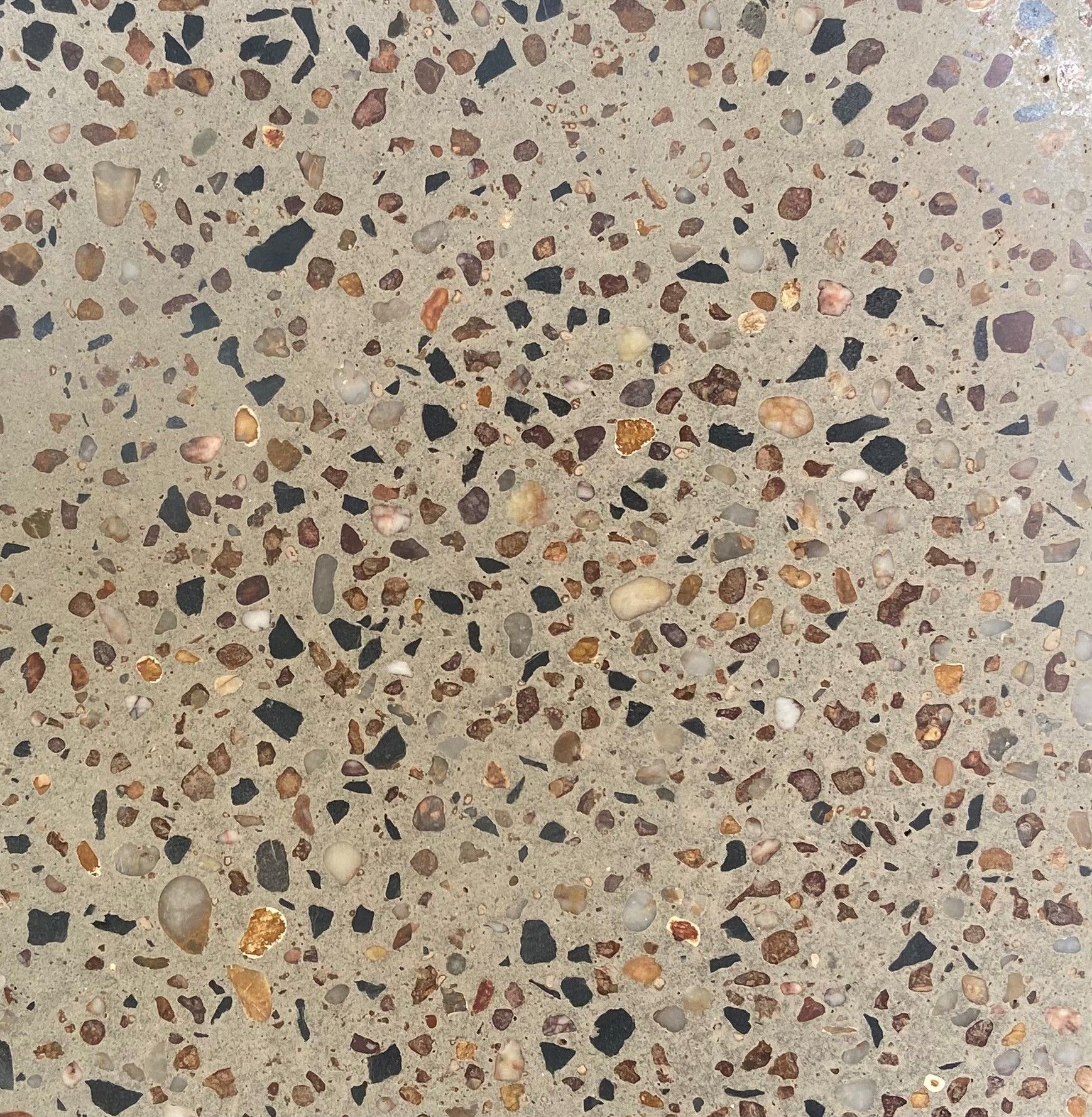

Nu Decorative® Polished Concrete

Polished concrete is seeing real growth as a durable, low-maintenance and non-allergenic flooring option - and it also looks amazing!

See below some examples of mixed aggregates and concrete - multiple colour combinations are available to suit your design requirements.

Note - The samples pictured are intended to act as a guide only and not an exact representation of the finished product; due to environmental factors and the natural raw materials used, the appearance may also vary. Images are provided as a guide only. Colour reproduction can vary significantly when viewing colours on your computer screen and other electronic mobile devices. We recommend viewing a physical sample prior to purchase.

Polished & Exposed White Concrete

Trend Alert - Introducing White Concrete by Nucon.

We all know that white never dates and compliments any surrounding colours that may be updated as trends come and go - white is the future-proof choice. Available in exposed, polished or broom finish. See sample images below.

Note - The samples pictured are intended to act as a guide only and not an exact representation of the finished product; due to environmental factors and the natural raw materials used, the appearance may also vary. Images are provided as a guide only. Colour reproduction can vary significantly when viewing colours on your computer screen and other electronic mobile devices. We recommend viewing a physical sample prior to purchase.

Coloured Concrete

WITH OVER 50 COLOURS IN THE RANGE, NUCON’S COLOURED-THROUGH CONCRETE IS AN ATTRACTIVE AND COST-EFFECTIVE ALTERNATIVE TO THE STANDARD GREY MIX.

Coloured concrete can be used on its own or combined with contrasting or matching coloured aggregates and surface textures to create just the right look. It can be used in just about any new concrete structure, including driveways, footpaths, patios, interior floors and tilt-up panels and columns. Full-depth colouring of the entire slab means that long-term colour performance is not a problem.

DOWNLOAD THE CCS BROCHURE TO VIEW THE RANGE OF CURRENT COLOURS

(Please use as a guide only. Colour reproduction can vary significantly when viewing colours on your computer screen and other electronic mobile devices. We recommend viewing a physical sample prior to purchase).

Standard Concrete

An extensive range of normal grey mix designs are available for commercial, government and residential applications.

Typical Mixes

- Residential Slabs (N20mpa, N25mpa, N32mpa)

- Residential Footings (N20mpa, N25mpa, N32mpa)

- Driveways (N20mpa, N25mpa, N32mpa, N40mpa)

- Footpaths (N20mpa, N25mpa, N32mpa)

- Pool Spray (S25mpa, S32mpa, S40mpa)

- Kerb and Channel (S25mpa, S32mpa)

- Block Fill (N20mpa, N25mpa, N32mpa, N40mpa)

- No-Fines (20mm, 10mm)

- Early Age Strength (speciality for high strength at an early age)

Standard premixed concretes are specified by strength, slump, and maximum aggregate size. Premixed concrete is also available to the engineer's specifications.

Concrete for Pools

Your pool surround can be created from a range of Nucon products, including exposed concrete with coloured oxides, coloured concrete or plain grey. Speak to one of our Concrete & Decorative Advisors today to find out which material and colours would best suit your requirements.

Our Nucrush team can assist you with any landscaping products you may need to provide the finishing touches to your pool surround area.

(Please use as a guide only. Colour reproduction can vary significantly when viewing colours on your computer screen and other electronic mobile devices. We recommend viewing a physical sample prior to purchase).

Concrete Driveways

Concrete driveways and pathways can be created from a range of Nucon products, including exposed concrete with coloured oxides, coloured concrete or plain grey. Speak to one of our Concrete & Decorative Advisors today to find out which material and colours would best suit your driveway - whether it's a brand-new driveway or upgrading an existing one - we are here to help.

Click here to watch a short step-by-step video showing the process of replacing a driveway with concrete supplied by Nucon.

Concrete Patios

Your entertaining area can be created from a range of Nucon products, including exposed concrete with coloured oxides, coloured concrete or plain grey. Speak to one of our Concrete & Decorative Advisors today to find out which material and colours would best suit your requirements - whether it's a brand new patio or upgrading an existing one, we are here to help - we will even try to help you colour match.

House & Shed Slabs

An extensive range of normal grey mix designs are available for your house or shed slab.

Typical Normal Mixes

- Residential Slabs (N20mpa, N25mpa, N32mpa)

- Residential Footings (N20mpa, N25mpa, N32mpa)

- Driveways (N20mpa, N25mpa, N32mpa, N40mpa)

- Footpaths (N20mpa, N25mpa, N32mpa)

- Pool Spray (S25mpa, S32mpa, S40mpa)

- Kerb and Channel (S25mpa, S32mpa)

- Block Fill (N20mpa, N25mpa, N32mpa, N40mpa)

- No-Fines (20mm, 10mm)

- Early Age Strength (speciality for high strength at an early age)

Standard premixed concretes are specified by strength, slump, and maximum aggregate size. Premixed concrete is also available to the engineer's specifications.

Another option for your house or shed slab is to use one of our polished concrete options, which could then also act as your flooring - polished concrete is seeing real growth as a durable, low maintenance and low allergen flooring option - and it also looks great!

Concrete Blocks

Concrete blocks are available from various Nucon Concrete Plants in Southeast QLD and Northern NSW.

Payment can be made via credit card or cash at the pickup location.

After midday is the preferred pick-up time for blocks, but please discuss this directly with the Nucon Plant when placing your order.

Long pants, a long sleeve shirt and enclosed shoes are required to be worn at the pickup location.

Product Information

Blocks are in various conditions and made from returned concrete varying in strength and colour. Some can also be in different colours, but most are grey. The Blocks are not engineered for a specific purpose.

- Type 1 - Full Rectangular Concrete Block 1400 x 700mm approx weight 1.56t ea

- Type 2 - Half Concrete Block 700 x 700 x 700mm approx weight 0.78t ea

- Type 3 - Large Concrete Block 900 x 900 x 900mm approx weight 1.75t ea

Nucon staff can assist with loading the block onto your vehicle when they are available if required, but the purchaser is responsible for arranging a pickup vehicle, transportation and unloading. The concrete blocks all include a 5-tonne lifting lug and reinforcement steel from the manufacturing process. The 5-tonne lifting lug enables the lifting of the block with a swift lift clutch.

These clutches can be purchased at the Nucon Plant for $165.00, including GST. If required, please request one in advance of pick up when placing your order.

Customer Information

The Nucon Concrete ‘Schedule of Surcharges' applies to all concrete products, to download click here.

Safety Data Sheet - Nucon Concrete Product

Pick Up Locations and Phone Number to Place an Order:

- Nucon Concrete Logan Ph 07 3841 3160

- Nucon Concrete Yatala Ph 07 3382 6551

- Nucon Concrete Oxenford Ph 07 5514 7400

- Nucon Concrete Southport Ph 07 5531 4169

- Nucon Concrete Ballina Ph 02 6686 0500

- Nucon Concrete Burleigh Ph 07 5525 7853

- Nucon Concrete Chinderah Ph 02 6674 3091

Product Guides:

To assist you, we have uploaded some industry guidelines to our website.

Guide to Concrete Placing Best Practice

Click below to read the CCAA Guide which outlines industry standard best practice for concrete placing.

This guide is written primarily as a reference guide for house builders and tradespeople working with concrete. Click here.

Concreting in Hot Weather & Tips to Minimise Plastic Shrinkage Cracking

The warmer months, with its strong heat and winds, are known to be the prime plastic shrinkage cracking season for concrete, with special care and planning required to protect your project. Please see information from the 2020 CCAA ‘Part V, Concreting Site Practices - Hot and Cold Weather Concreting, available to read by clicking here.

“Rapid drying of the surface of the plastic concrete causes it to shrink and crack, but the cracks are not always evident during finishing operations and may not be discovered until the next day.

WHAT CAUSES PLASTIC SHRINKAGE CRACKS?

Simplistically, plastic shrinkage cracking occurs when the rate of evaporation of moisture from the surface exceeds the rate at which moisture is being supplied to it (via bleeding from the concrete).

The concrete surface dries out and shrinks at a time at which it has little strength and hence it cracks. It can be likened to the cracking that occurs in clay soil as it dries. Water is lost from the concrete mass in two main ways:

- Drying from the top - Moisture rises to the top surface of a concrete element during placement – a process known as bleeding. Bleed water dries out mainly from evaporation; when the rate of evaporation exceeds the rate of bleeding, the surface dries and tends to crack.

- Drying from the base - Water in a concrete slab may be absorbed into the subgrade or ground below. In addition to affecting bleeding this could significantly increase settlement of concrete and the risk of associated cracking.

PRACTICES TO MINIMISE PLASTIC SHRINKAGE CRACKING

- Dampen the subgrade and formwork, ensuring that any excess water is removed prior to placing concrete.

- Protect concrete surfaces from drying out -

- Erect wind breaks to reduce wind velocity over the concrete surface. This is often impractical, but can be accomplished when frames or walls are erected prior to a floor being placed.

- Apply aliphatic alcohols over the surface immediately after screeding and while there is plenty of bleed water on the surface; repeat the application in severe conditions. These products reduce the rate of evaporation from the surface. They are not a substitute for curing.

- Commence curing regime promptly after finishing and continue for the specified period.

- The use of sufficient proportions of synthetic or steel fibers in concrete can provide improved control of plastic cracking”.

Explore our Concrete Products page to discover our wide range of premium solutions.